1-1. Application field:

Widely used in 3D dimension measurement, flatness measurement, contour measurement, etc. of glass, machinery, electronics, molds, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision hardware, precision stamping, plug connectors, household appliances, computers, LCD TVs, circuit board PCBs, automobiles, medical devices, clocks, instruments, etc

2-1. Instrument quality:

The base is made of (00 grade) marble material and has a sturdy platform design, ensuring extremely high stability and rigidity.

Beautiful appearance design and more user-friendly functional design; Rational Vue software from the United States has a user-friendly interface, powerful functions, simple operation, strong stability, and programmable automatic measurement.

Adopting precision ball screw and precision linear guide rail, combined with high-performance AC servo system for full closed-loop control, high precision, high speed, and high stability.

Adopting high-resolution brand color CCD to ensure high-quality measurement images and improve fast measurement speed.

Equipped with a card position zoom lens, pixel calibration (linear calibration) is not required after changing the magnification.

Software controlled LED surface lights and straight axis LED contour light sources for the fifth ring and eighth zone.

High precision open grating ruler 1 μ M.

2-2.仪器特点:

Product Introduction:

The VMC series is a fully automatic laser planar measuring instrument launched by our company. The X/Y/Z axis adopts a fully closed-loop servo control system, combined with high-precision lenses, and the U axis adopts a stepper control system. Other ranges can be selected, making it very convenient to achieve precise measurement of various complex surface workpieces. It can achieve fully automatic optical measurement software, which enables large-scale and rapid detection of workpieces, and also has SPC data analysis function.

Product features:

1. 4-phase programmable LED cold light source for surface measurement of various complex workpieces, resulting in higher measurement accuracy.

2. Laser can be added to achieve precise height, flatness, contour and other arbitrary scanning.

3. Full mouse/joystick operation, simple and easy to use.

4. Three axis CNC control system.

5. Real Vue fully automatic image measurement software。

Technical parameters:

Specific model | VMC400SL |

(X/Y/Z axis) Measurement stroke (mm) | 400*300*200 |

Full machine size(mm) | 980*650*1650 |

Machine base and column materials | 高精度花岗石 |

CCD | Japanese brand color CCD |

X. Y-axis measurement accuracy | (3+L/200)μm |

Magnification rate | Step Zoom optical magnification: 0.7X-4.5X, image magnification: 28X-180X |

Resolution of optical ruler | 1μm |

repeatability | 2μm |

operating mode | 自动 |

power supply | 110/220V |

Suitable temperature and humidity | temperature:19°--24°,humidity:45%--75% |

Warranty period | 1 year |

Application field:

Mass and rapid testing of PCB boards, mobile phone accessories, connectors, mechanical accessories, etc

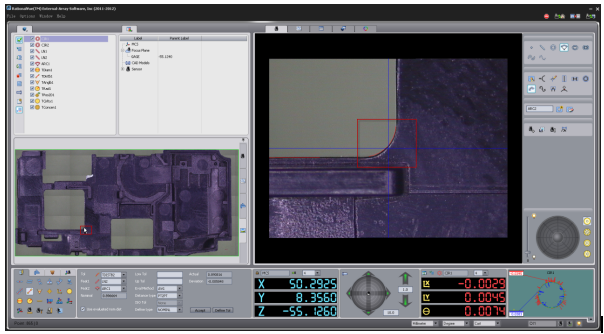

4-1.Software Introduction:

The main features of Rational Vue are:Support for Win7 operating system

Support for Windows 7 or above operating systems, and its interface fully conforms to contemporary Windows style

Adopting modular design and drag and drop operation mode. Completely avoiding problems such as complex windows popping up, multiple operation steps, and redundant interface stacking in traditional software, the vast majority of Rational Vue functionality implementation only requires 1-2 mouse drag and drop operations.

一套软件,一个完整的解决方案

Quick and efficient operation

N Automatic program

Images, probes, coordinate systems, autofocus, magnification, brightness adjustment, CAD theoretical element recognition, automatic comparison measurement, element construction, tolerance calculation, and output can all be simultaneously added to a program and automatically run.

The program modification is convenient and fast. It is possible to quickly modify the lighting, magnification, height, and measurement sequence of the program

The elements under the same screen are automatically measured by the machine without movement

Adopting world advanced algorithms to improve overall machine performance and accuracy

N Complete machine compensation algorithm

支持机器21项误差补偿:线性、直线度、角摆、垂直度… 支持Z轴自转补偿、Z轴垂直度补偿(用平行平晶、直角规)、Z轴探针补偿(用探针)镜头XY比例校正 支持OEM补偿加密 支持多层空间面补阵,最大限度提高机器的测量精度 | 软件内置玻璃线纹尺、面阵补偿板自动程序,可协助快速取得补偿数据,使机器补偿效率大大提高,降低用户的人力误差和时间成本 |

After comparative testing, the accuracy and repeatability of the image measuring machine using Rational Vue software have been significantly improved

Subpixel algorithm

The application of advanced sub pixel algorithms greatly reduces the impact of software on measurement accuracy in optical measurement.

Fully functional and powerful

The most complete geometric measurement

n Workpiece puzzle&navigation

n Special edge measurement

Burr filtration

Special edge treatment

Focusing measurement height and flatness

n RtionalVue具有专业的针对网板的测量工具,可轻松的实现网板直线的测量。适用于太阳能、电视等行业的网板测量

The most complete calculation of geometric tolerances (including 2D and 3D, shape tolerances, positional tolerances, shape or positional tolerances). Strictly following international GD&T evaluation standards, with multiple standards such as ISO (including German DIN standards), US Y14.5M, and GB.

Distance, angle, diameter, radius, cone angle

Straightness, flatness, roundness, cylindricity, verticality, inclination, parallelism, symmetry, concentricity, coaxiality, positional (2D&3D), point profile, curve profile, surface profile, circular runout, total runout

Can output various reports such as PDF, Excel, TXT, Html, images, etc

Dimension and tolerance annotations: distance, angle, radius, diameter, roundness, straightness, positional accuracy, reference element markings

FormError graphics: Set up upper and lower tolerance zones, color display graphic trends, maximum and minimum display, spacing display errors