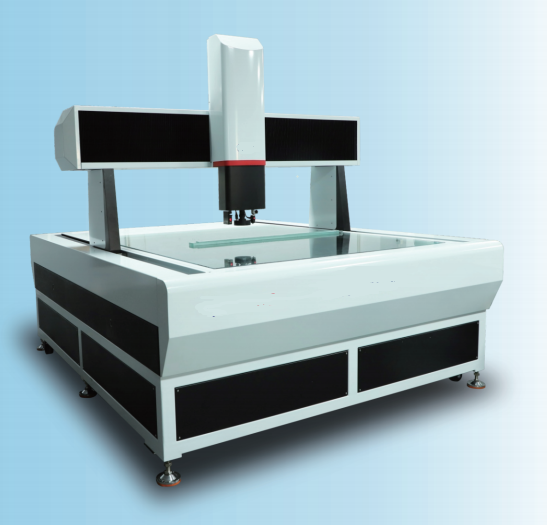

The large stroke fully automatic optical image measuring instrument is designed for large-scale inspection and is suitable for large-sized workpieces such as LCD panels, large and medium-sized sheet metal parts, PCB boards, TFTs, stamping parts, film films, etc. It is paired with fully automatic control software to achieve batch size control

Product Features

1. The entire frame is made of natural marble, which never deforms, has high precision, and high stability

2. A new streamlined design with a neat, intuitive, and generous appearance

3. Gantry structure with servo control technology for smooth and fast operation

4. Full joystick/mouse operation, simple and easy to use

5. The bottom light and surface light use adjustable LED cold light sources, which can achieve precise measurement of various complex surface workpieces

6. Powerful measurement software that can conveniently and quickly measure various workpieces accurately, providing users with a comprehensive measurement solution

7. Optional laser, probe, etc. to improve 3D measurement accuracy

Technical Parameter

Fully automatic NAVITAR zoom lens

| Model | VMC500 | VMC700 | VMC1200 | VMC1500 |

| Full machine size(mm) | 1800*1300*1500 | 2000*1500*1500 | 2500*1900*1500 | 2800*2100*1500 |

| Measuring stroke(mm) | 500*400*200 | 700*600*200 | 1200*1000*200 | 1500*1200*200 |

| Machine weight(Kg) | 2000 | 3000 | 8000 | 11000 |

| Machine load bearing(Kg) | 30 | 40 | 50 | 50 |

| Machine base and column material | High precision granite grade 00 | |||

| operating mode | automatic | |||

| Motor control mode | Imported screw drive | |||

| shot | | |||

| Magnification rate | Step Zoom optical magnification: 0.7X-4.5X, image magnification: 23X-160X | |||

| CCD | High definition color 1/2CCD (optional with 2.2 megapixel CCD) | |||

| Resolution of grating ruler(um) | 1μ M optional with 0.5 μ M | |||

| X/Y Axis repeatability(um) | 3 | |||

| X/Y Axis repeatability(um) | (4.5+L/250) | |||

| Z Axis repeatability | 4.5 | |||

| speed(mm/s) | X axis :300 Y axis:300 Z axis:30 | |||

| acceleration(mm/s) | X axis:300 Y axis :800 Z axis:300 | |||

| light source | Upper surface light: Zone controlled eight item light, lower contour light: LED directional light | |||

| software | Inspec 3D | |||

| Usage environment | Power supply: 220V ± 10% 50HZ Temperature: 20 ± 5 ℃ Humidity: 45% -75% | |||

Widely used in machinery, electronics, molds, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision hardware, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, computers (computers), liquid crystal televisions (LCD, OLED), printed circuit boards (circuit boards, PCBs), automobiles, medical devices, clocks, instruments, etc.