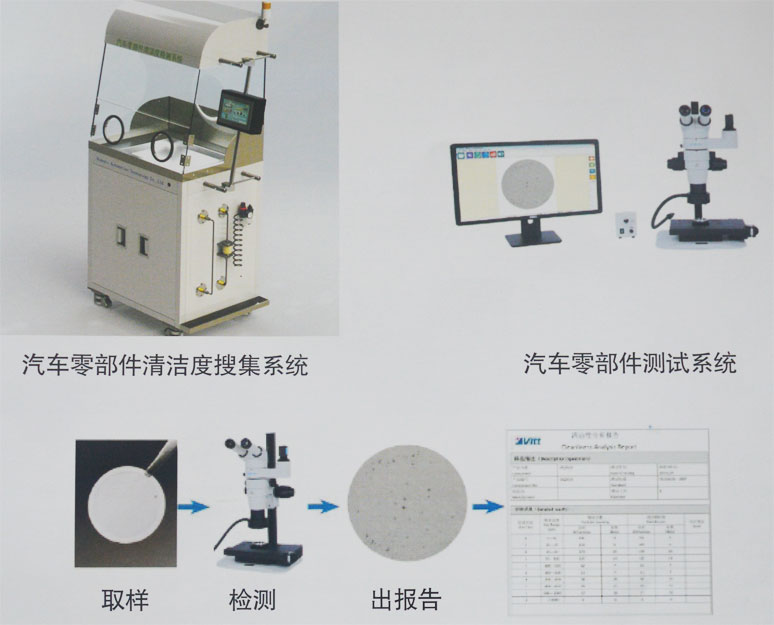

This automotive component cleanliness collection system meets the requirements of a fully enclosed 100 level purification space, and the parts are cleaned using cleaning fluid. The cleaning solution and purified air are subject to self inspection and self-cleaning, and the filter membrane automatically recovers the cleaned residue. The cleaning solution is circulated and filtered, and can be reused. Collaborate with our company's visual inspection equipment to detect and analyze parts and residues. The cleanliness detection and analysis system complies with ISO16232 VDA19 ISO04406 ISO4407, GB/T-20082, and is an authoritative product for cleanliness detection in the automotive industry and particle size detection in the hydraulic and lubrication industries.

Collect system technical parameters:

·Cleaning area size (W * D * H): 600 * 500 * 700mm (customizable according to customer requirements)

·Maximum bearing capacity: 100KG

·Internal material: 304 mirror stainless steel

·Working air source: 0.4-1.0 MPa

·Noise: < 60dB

·Cleaning pressure: 0-5bar, continuously adjustable

·Vacuum negative pressure: maximum 660mmHg (-0.88bar)

·Liquid storage tank: 15L * 2

·Precision of fine filtration recovery filter: 0.22 μ M

·Pressure tank outlet filtration accuracy: 0.45 μ M

·Applicable detection filter membrane: ∅ 47mm (or specified by the customer)