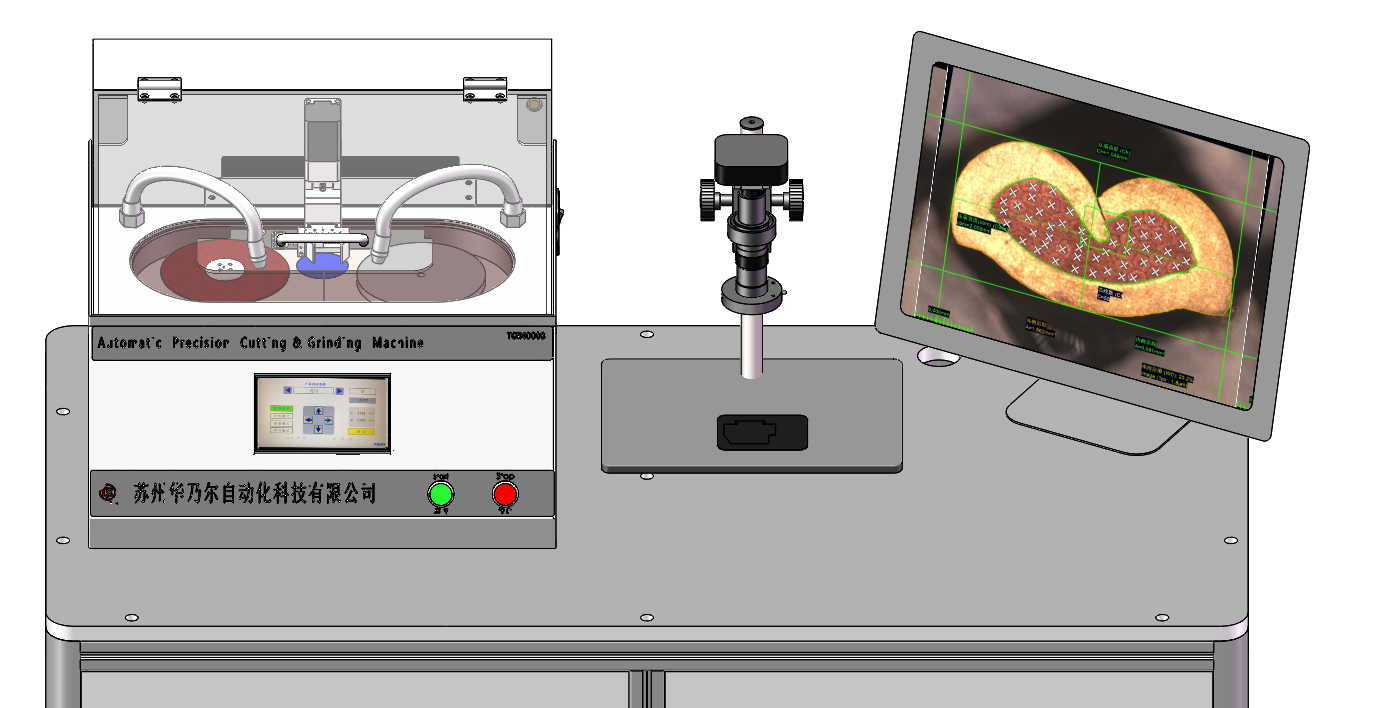

1、 The principal tangent grinding integrated machine is a comprehensive touch screen terminal cutting and grinding instrument: water-cooled precision automatic cutting and grinding. The applicable range of wire diameter is 0-30mm. This system is suitable for terminal cross-section analysis and testing requirements in industries such as automotive, home appliances, and electronics.

2、 System Characteristics

1. No resin solidification required

Previously, resin solidification and hardening cutting; Then rough grinding, polishing, time-consuming and laborious, making a sample takes several hours. Now this product does not require resin solidification, and the ordinary sample is completed in about 5 minutes.

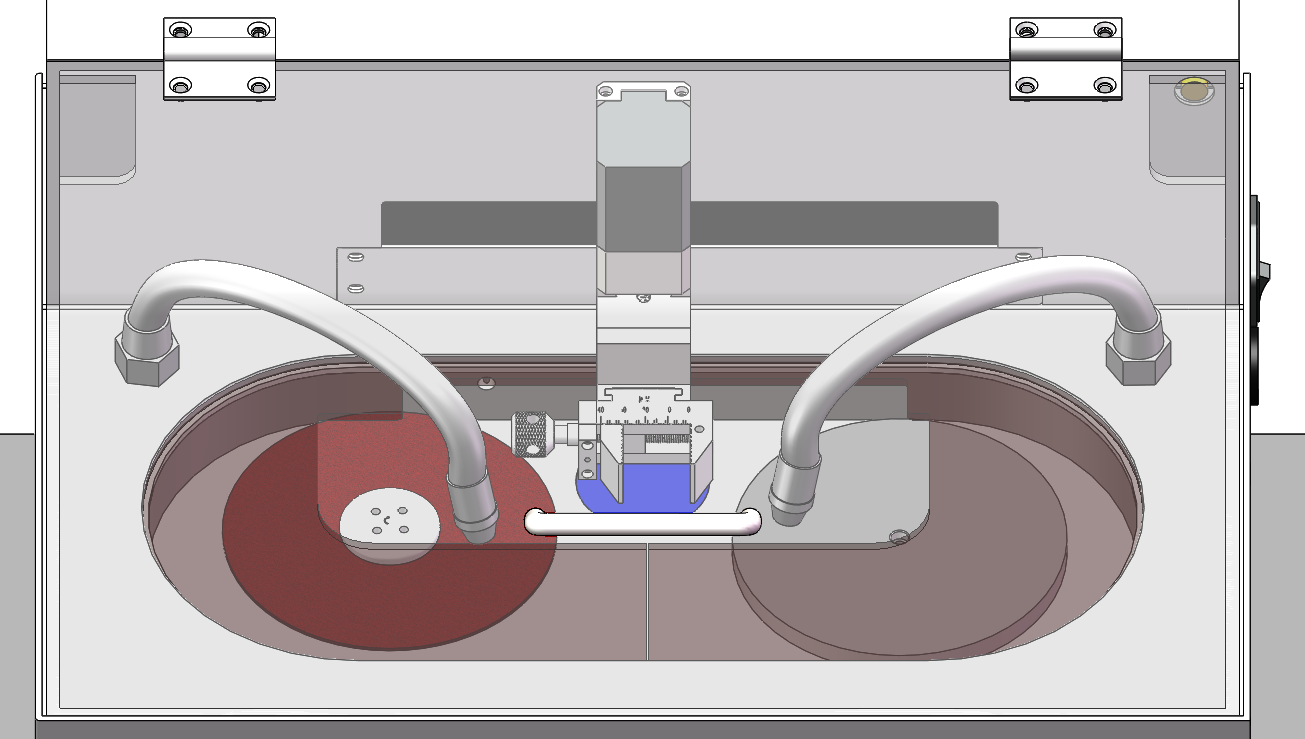

2. Water-cooled fully automatic cutting and grinding integrated machine

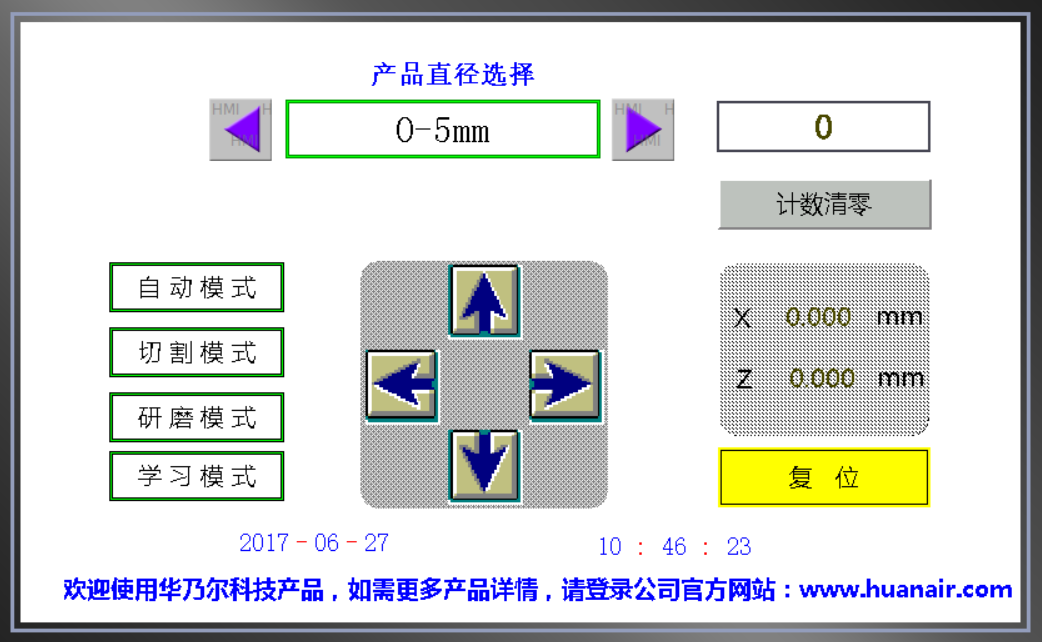

This cutting and grinding all-in-one machine can achieve precision cutting and grinding, with full water cooling. There are four modes, including automatic mode, cutting mode, grinding mode, and "learning mode". This mode can be operated according to pictures (exclusive to the industry); Customers can even customize parameters for personalized cutting and polishing, with arbitrary cutting positions and positioning accuracy within 5um, without damage to cutting and polishing.

3. The cutting and grinding machine table has a 7-inch touch screen cross-section in both Chinese and English, with no pressure during operation

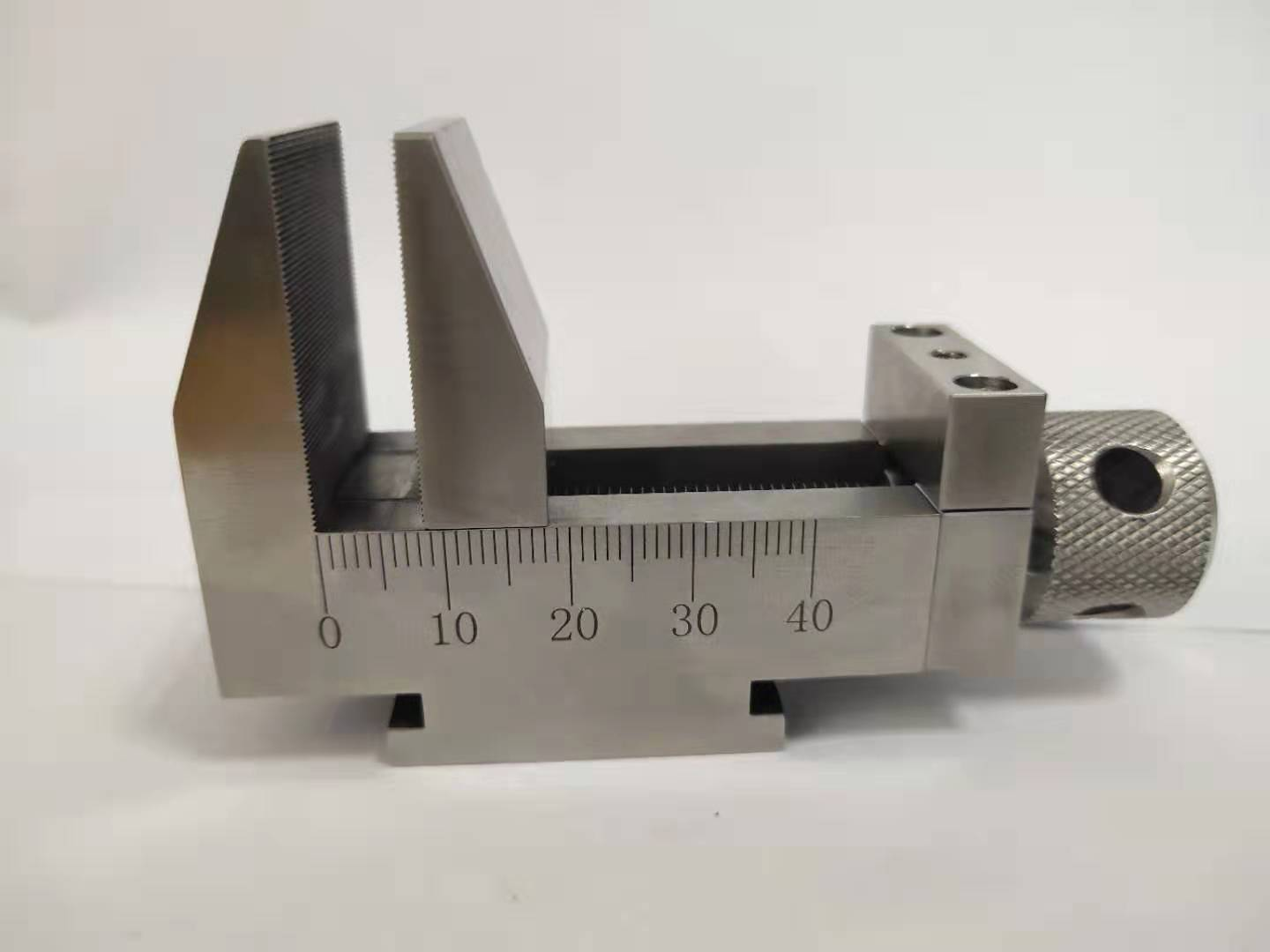

4. Special fixtures can correspond to samples of various sizes

Exquisite stainless steel material fixture, fine tooth clamping, a good assistant for precision cutting, corrosion-resistant;

3、 System Structure and Configuration

1. German SEW motor high-power precision cutting motor (can achieve power outage stop and continuous cutting functions); Shinano precision grinding and automatic lifting motor from Japan;

2. Color high-definition 7-inch touch screen control

3. Misumi ball screws from Japan and silver slide rails from Taiwan;

4. X-axis Shinano motor;

5. Applicable range of the product: cutting and grinding diameter 0-30mm, positioning accuracy 0.01mm,

6. Power supply: AC100V~AC240V, power: 2500W

7. Cutting blade: Φ 150X1.0mm or 0.5mm (optional)

8. Grinding sandpaper: Φ 150mm/1500 # (or 2000 # optional)