The FPC laser coding machine is a laser processing equipment that integrates optical, mechanical, electrical, and material processing. Its processing advantages include:

1. Non contact machining, with a small heat affected zone of the components during the machining process;

2. High performance UV laser with small light spot, uniform power distribution, small thermal effect, small coding slot width, and high coding quality;

3. Precision two-dimensional workbench and fully closed-loop CNC system;

4. Position sensor and CCD image positioning technology, automatic positioning and focusing;

5. Code typing and re reading verification;

6. Automatic stacking technology;

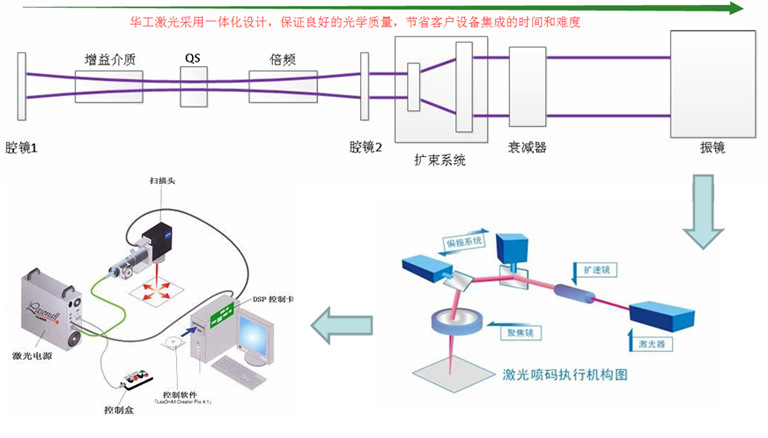

一、Principles of Laser Coding Machine

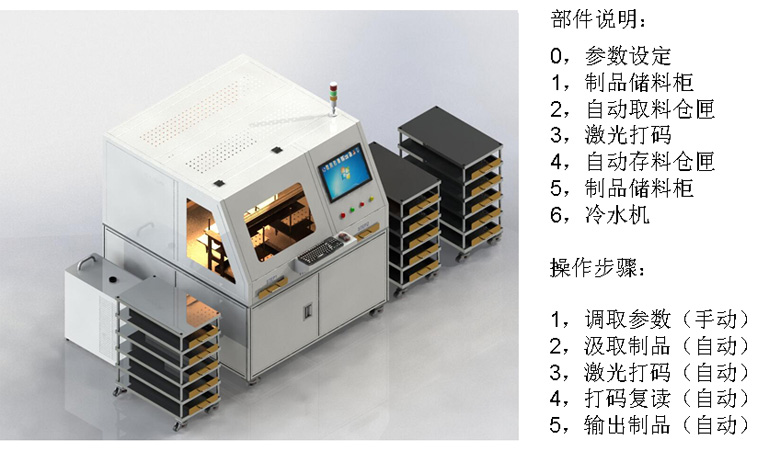

二、激光打码机结构

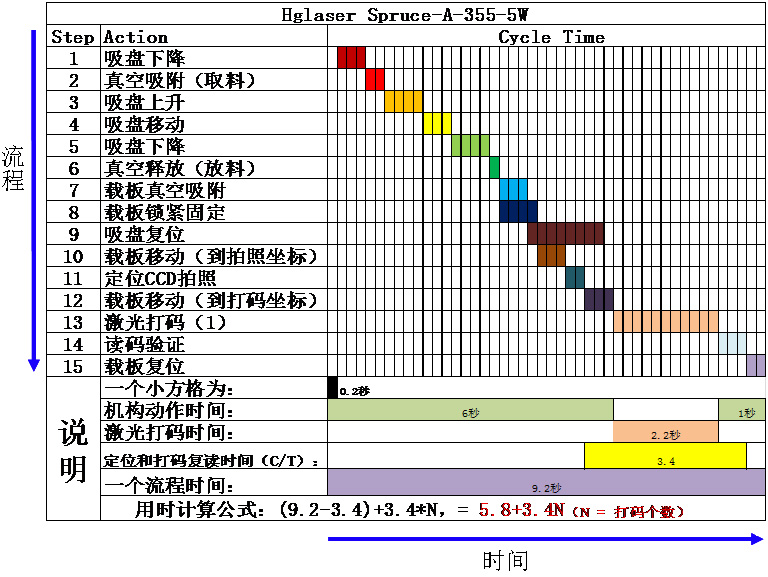

三、激光打流程

四、激光打印产品